Sanitary stainless steel equipment is essential in the production of food and pharmaceutical products. Smooth polished surface can help to decrease the growth of microorganisms and strengthens corrosion resistance. Here at Qiangzhong, we apply the four types of polishing methods shown below:

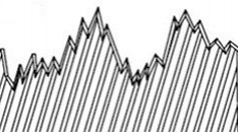

- Mechanically Polished, MP

It can increase surface roughness and texture with precision grinding but does not change the surface morphology and the number of dielectric layers.

-

Original Surface

Original Surface -

Polished Surface

Polished Surface

-

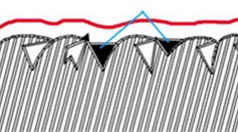

- Buffed Polished, BP

It is a common polishing method for stainless steel. Although the polished product has good roughness, you may find many cracks and defects if inspected by electron microscope. Impurities and abrasive grains are imbedded in the surface.

Polishing paste can become trapped in recessed areas, potentially contaminating the processed products.

-

Original Surface

Original Surface -

Polished Surface with Polishing Paste Residue

Polished Surface with Polishing Paste Residue

-

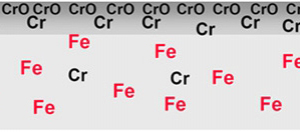

- Pickled & Passivated / Chemically Polished, AP / CP

It can remove grain residues on the surface but does not affect the surface roughness and the number of dielectric layers. It forms a chromium oxide film on the surface to protect it from corrosion and oxidation.

-

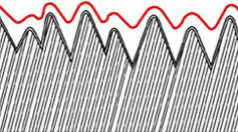

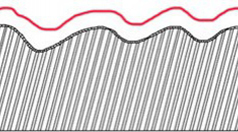

- Electro Polished, EP

It can drastically improve the surface morphology and structure, decrease defects and attaining the least number of dielectric layers. It forms a thick and closed chromium oxide film on the surface.

-

Original Surface

Original Surface -

Polished Surface

Polished Surface

-

Founded in 1999, Wenzhou Qiangzhong Machinery Technology Co. has been devoted to the production of sanitary mixing and liquid processing equipment. Manufactured from high precision stainless steel, our main products include colloid mills, mixers, agitators, sanitary pumps, sanitary filters, diverse tanks and vessels. They are utilized by companies operating in food, dairy, beverage, pharmaceutical, and chemical industries.

Read More