JMW Stainless Steel Sanitary Colloid Mill

Colloid mill machine, Sanitary processing equipment

JMW sanitary colloid mills utilize stator-rotor combinations to graduate the stator-rotor gap for a highly accurate fineness adjustment. In this type of colloid mill, subject materials can be ground over and over again. Taking sanitary factors into consideration, we use stainless steel to produce the rotor and the stator.

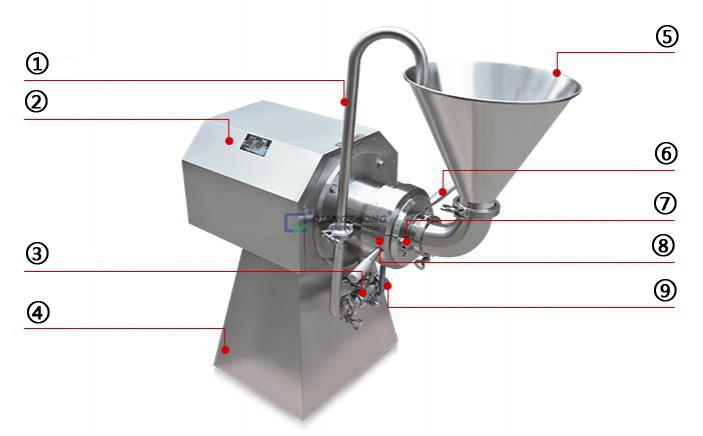

- Circulation Pipe

- Motor Cover

- Three-way Valve

- Base

- Hopper

- Handle

- Cooling Pipe Fittings

- Adjust Disc

- Outlet

| Model | Power (kw) | Speed (r/min) | Fineness (um) | Production(t/h) | Diameter of Scafe (mm) | Cooling Pipe (mm) | Outlet (mm) | Inlet (mm) | Weight (kg) | Dimensions(LxWxH) mm |

| JMW-80 | 3 | 2900 | 2-40 | 0.3-1 | 80 | 12 | 25 | 48 | 75 | 630x380x790 |

| JMW-100 | 5.5 | 2900 | 2-40 | 0.5-2 | 100 | 12 | 25 | 66 | 115 | 680x370x900 |

| JMW-120 | 7.5 | 2900 | 2-40 | 0.5-3 | 120 | 12 | 32 | 66 | 120 | 680x370x900 |

| JMW-140 | 7.5 | 2900 | 2-40 | 0.5-4 | 140 | 12 | 32 | 66 | 160 | 680x370x900 |

-

With the exception of the motor, all parts that have contact with materials are made of sanitary stainless steel to resist contamination.

-

The maximum rotational speed of colloid mill can reach 2900 (r/min), capable of crushing materials instantaneously.

-

Colloid mills can adjust the degrees of fineness in order to serve different materials efficiently.

-

Quick changeover makes it simple to install and easy to clean.

Inquiry

Welcome to Wenzhou Qiangzhong Machinery Technology Co., Ltd.!

Please contact us anytime in the following forms. On receiving your messages, we will reply to you as soon as possible and provide the corresponding service.

No. 5, Zhaoxia South Road, Shacheng, Economic and Technological Development Zone, Wenzhou, Zhejiang Province

Tel.: +86-577-86809777

Founded in 1999, Wenzhou Qiangzhong Machinery Technology Co. has been devoted to the production of sanitary mixing and liquid processing equipment. Manufactured from high precision stainless steel, our main products include colloid mills, mixers, agitators, sanitary pumps, sanitary filters, diverse tanks and vessels. They are utilized by companies operating in food, dairy, beverage, pharmaceutical, and chemical industries.

Read More